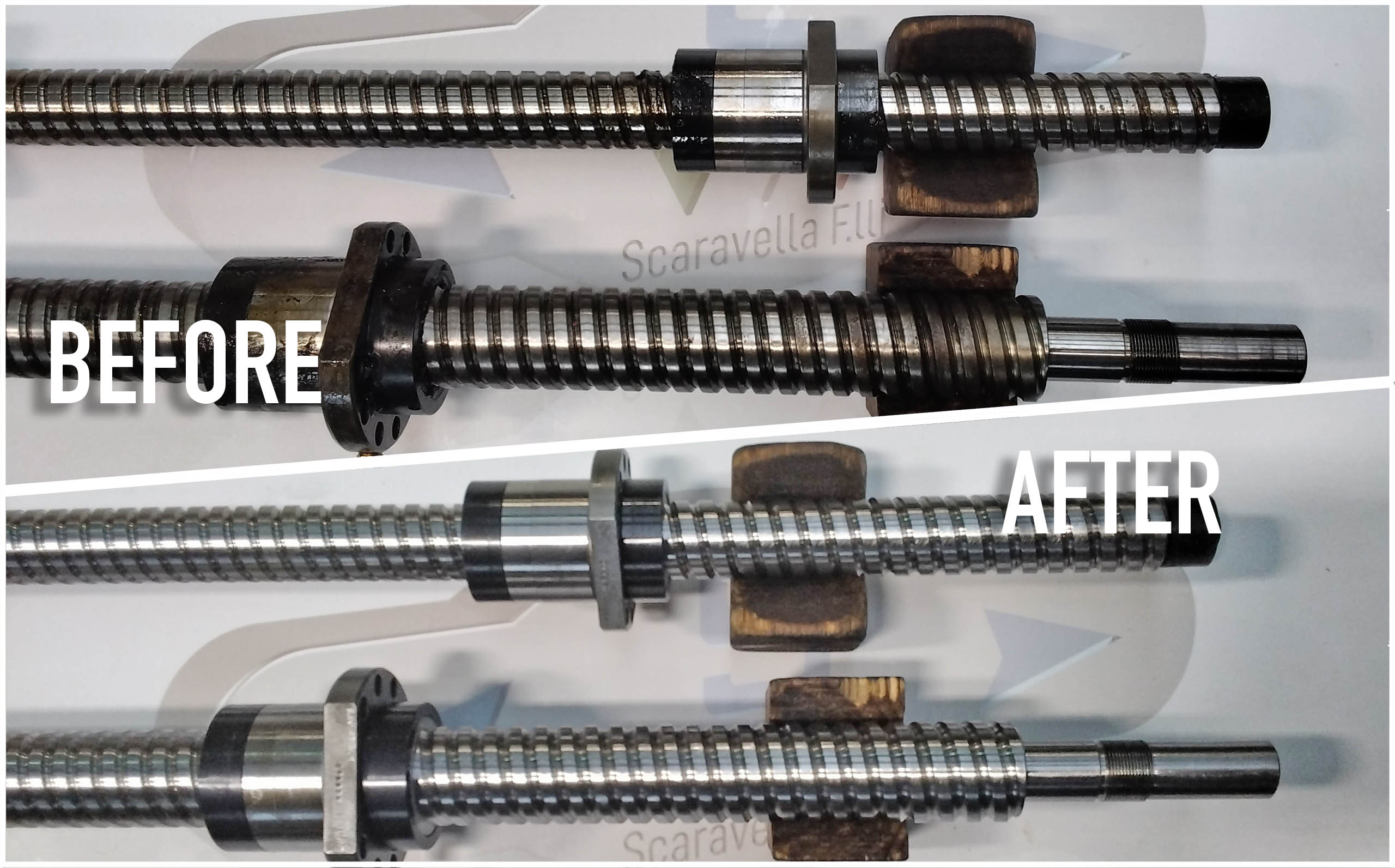

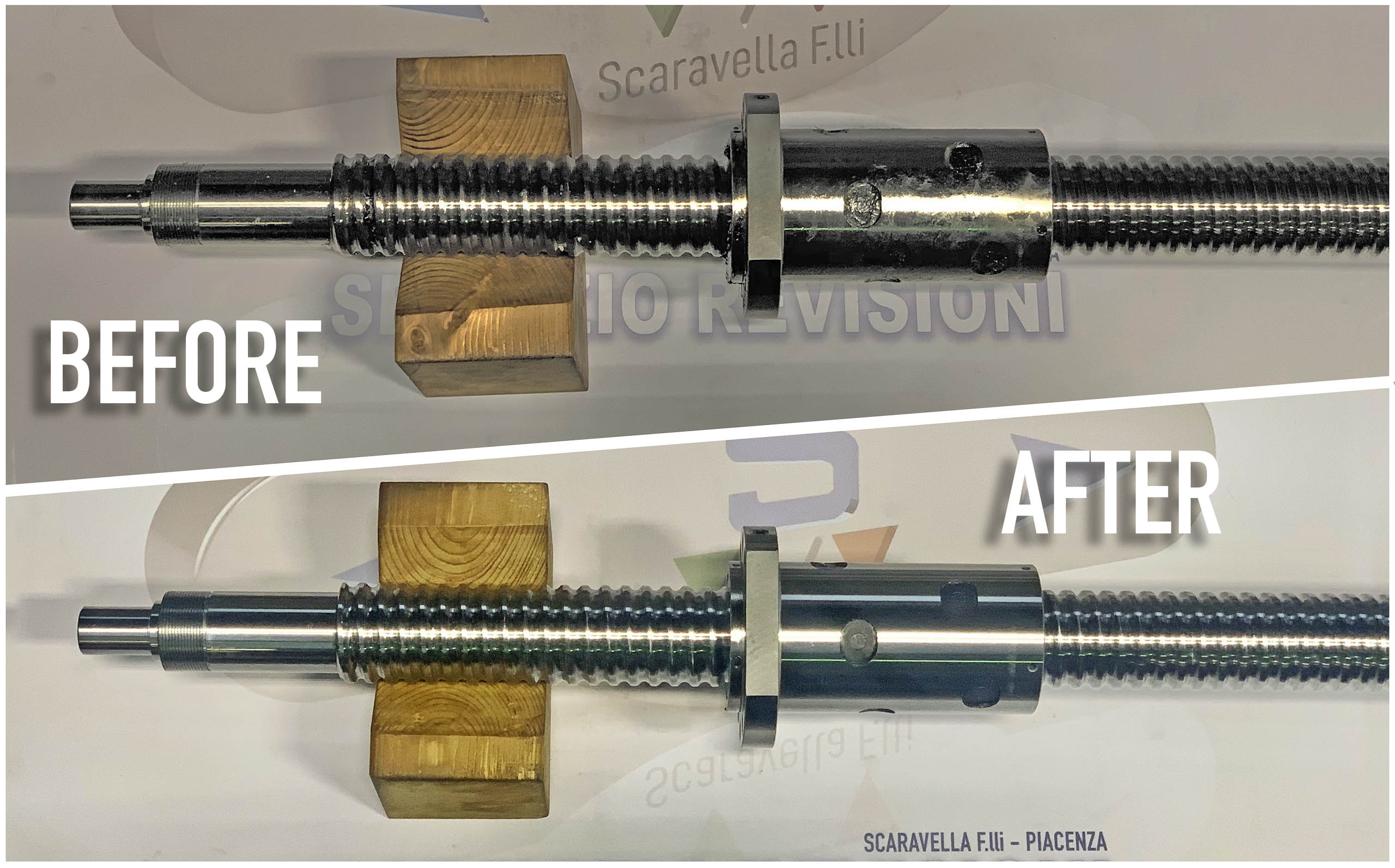

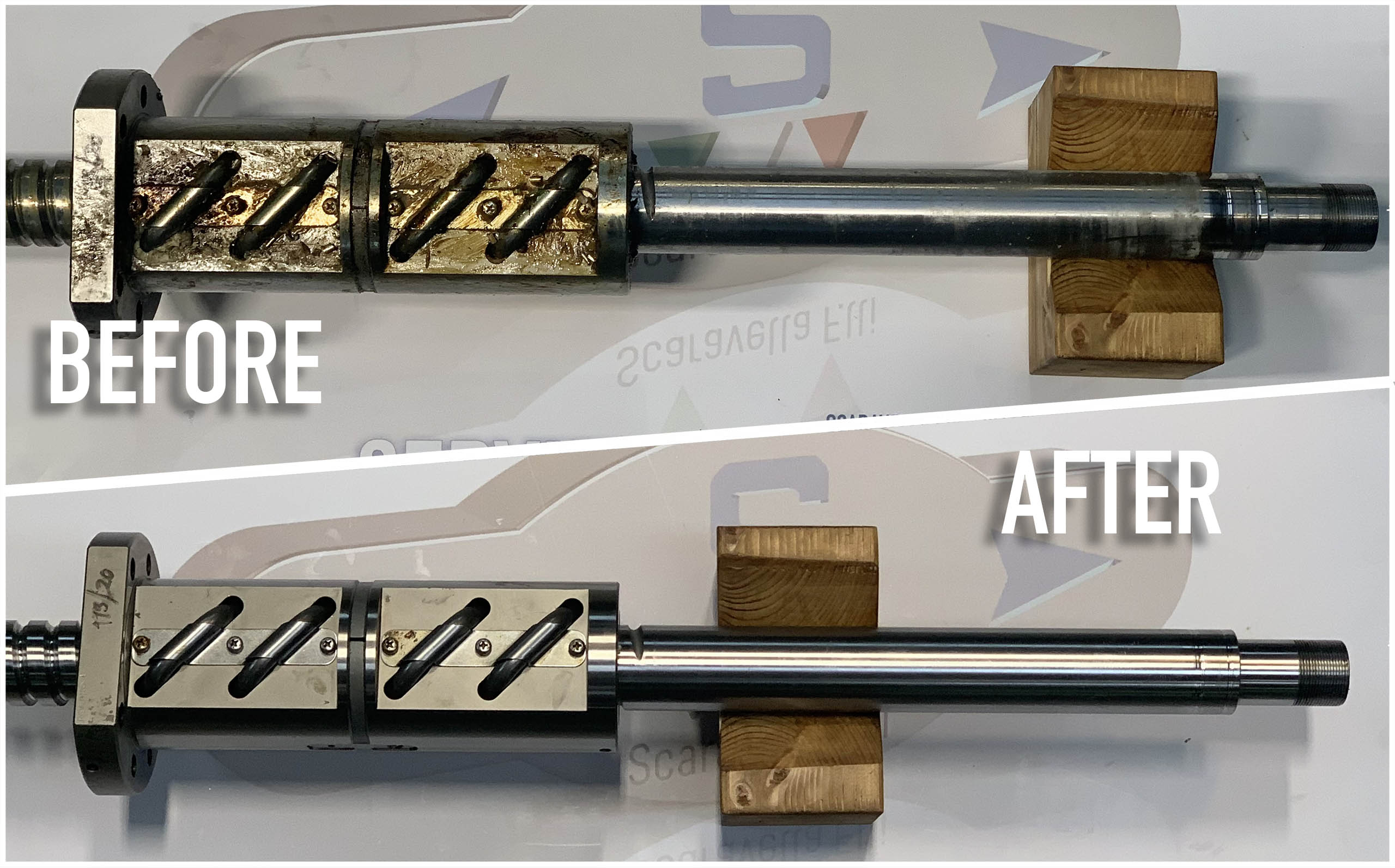

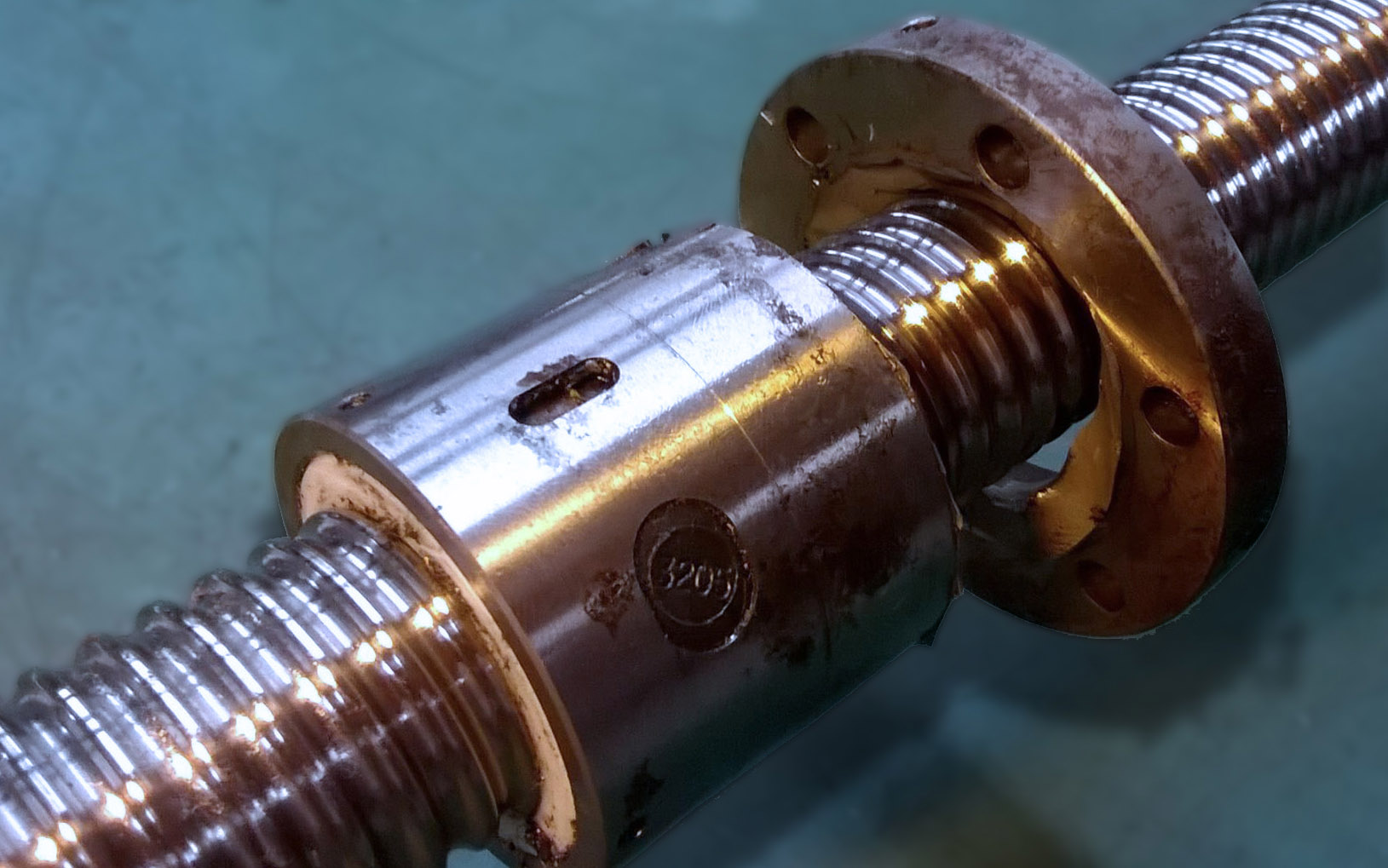

Jamming, discontinuity in movement, noise during work show the decay of the screw and nut system which, over time, lead to machine downtime. Scarce lubrication, the contact of the ball screw with the machining residues as well as particularly severe operating conditions often worsen the wear of the parts and reduce the life of a screw. When facing such a situation, the technician appointed to the repairs can only replace the screw – nut system.

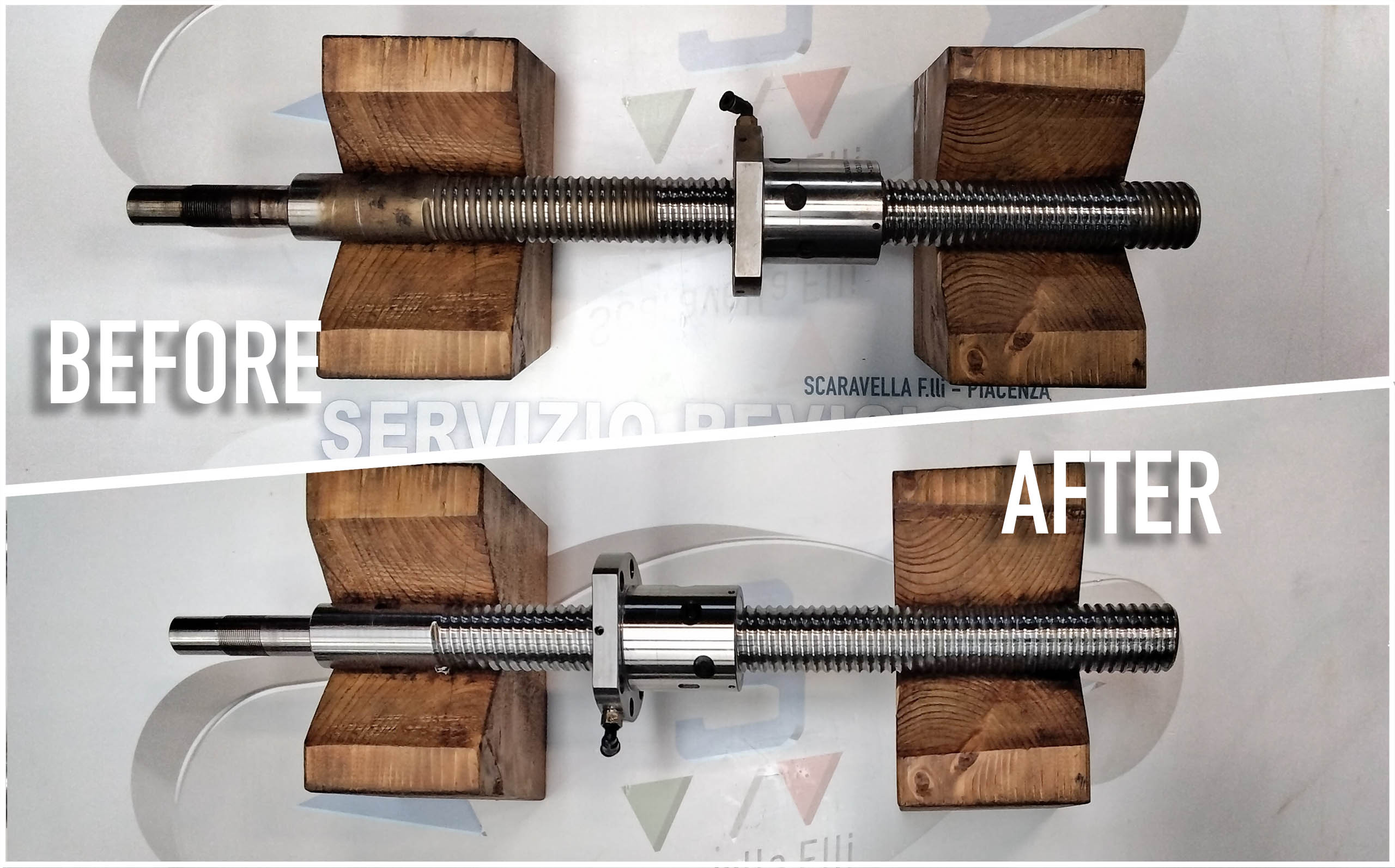

It isn’t always necessary to replace the ball screw with a new one; the experience of our testing technicians, the processing quality and the precision of our testing instruments allow our Overhaul Department to check the screws produced by any Manufacturer, to accurately evaluate their conditions and to restore, whenever possible, their previous operational features.